WALKING MACHINE

Higher, Faster and Stronger

Problem Statement

If given two RC servo motors, how to drive a walking machine to "walk" forward, as servo motor could only rotate back-and-forth instead of unidirectionally.

Solution Inspiration

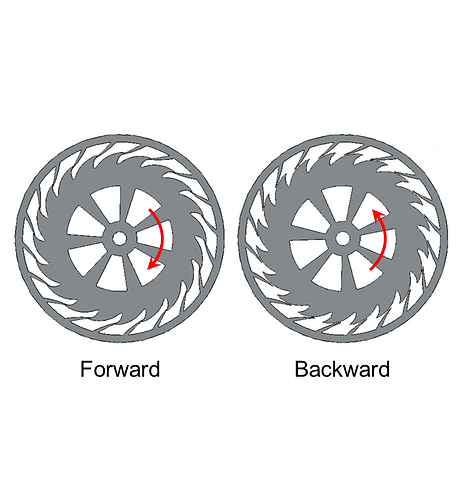

The ratchet wheel (inner wheel) is mounted on the servo motor, and the pawl wheel (outer wheel) is connected to the main wheel.

When the ratchet wheel rotates in the clockwise direction, ratchet wheel and pawl wheel will lock by themselves. In this way, the servo motor can drive the main wheel to go forward. When the ratchet wheel rotates in the counterclockwise direction, the pawl wheel will lose the lock with ratchet wheel and the main wheel will not be driven to move forward.

Final Design

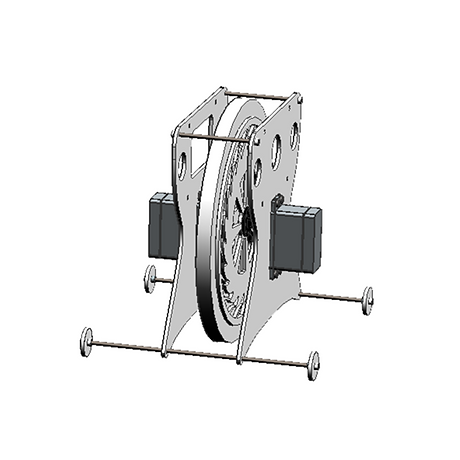

Two pairs of ratchet wheels and pawl wheels are mounted on both sides of the large main wheel in the middle.

Exploded Diagram

The exploded diagram shows all components including servo motors, servo mount, ratchet wheel, pawl wheel, main wheel, stationary axis, ring, truckle, bearing, servo disk, nut, and screw.

Assembly Animation

The video shows the whole assembly process of the walking machine and simulates the performance of it.

Physical Prototype

The body of the machine is made of acrylic board by using laser cutting. Four long copper cylinders are used to connect them together.

Personal Contribution, Reflection, Discussion

My personal contributions in this design are brainstorming the idea to drive machine with servo motor. All the visuals are created to show different work of different design stages.

In the design process, we were assigned a task to build a walking machine driven by two servo motors. The challenge was to design a mechanism to transfer the back-and-forth rotation of motors to the boost power of the machine. Then the wind-fire rings inspired us of ratchet wheel and pawl wheel mechanism. We began to build the CAD model and assembly animation of the machine, and finally built the physical model that really worked.

The animation we created clarify the design details of the machine, and my skills of doing animation were also strengthened. The next steps of this project are to do the design revision according to the test case under different road surface conditions.